Dr. Gary Wang, Prof., P.Eng., ASME Fellow, CEO, Empower Operations Corp.

On Dec 1, 2012, seven years ago from today, the editor of Digital Engineering in his article titled “Simulation-Driven Design Drives Innovation” stated :

“This should be the decade where design optimization finally emerges from the province of university research and specialist groups within the aeronautics and automotive industries to take its place in the mainstream of engineering product design. Industrial-strength commercial software is now available in the marketplace, and is becoming increasingly accessible to designers as the trend to incorporate engineering analysis into CAD products gathers momentum”

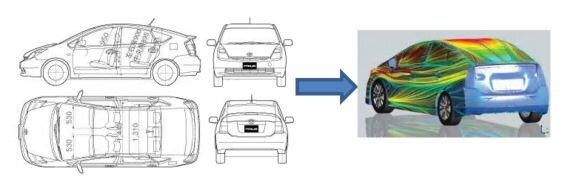

In the past 20-30 years, computer aided drafting and engineering analysis/simulation technologies have seen a rapid growth. Design engineers can produce engineering drawings with ease and analysts perform engineering simulation for design verification. When it comes to design revision, however, it still largely depends on human intuition and experience. In most of manufacturing companies, design and simulation belong to two independent departments. Design engineers design the product and then pass the design to the analysis department for verification. If the design passes the technical specifications, the design enters to the prototyping and testing phase or directly to production. Both the analysis and the test departments can pass their feedback to the design department for design revisions. The entire cycle from design to production is lengthy and costly. Only a limited number of design iterations are possible, given the high cost and long cycle time. Below shows an example of car shape design for aerodynamic performance. The first step is engineering design; the second shows the aerodynamic simulation. The question is, can we incorporate simulation to find better designs, and how?

Figure 1 Simulation is used only for design verification in industry.

The trend, as the editor of Digital Engineering perceived, leads to simulation-led design, or model-based systems engineering (MBSE), or optimization-driven design. The essence is to loop the design-analysis-redesign with the feedback from simulation, as shown in Figure 2. With a fast-growing number of engineers become familiar with simulation technologies , the prevalence of computing power and the maturity of industry optimization tools, this trend is becoming reality.

Figure 2 Optimization-driven design process.

Let’s take a look at the movement in the commercial optimization software market:

- 2009, Dassault Systems acquired Engineous Software, the developer of Isight, leader of the design optimization field

- 2010, Cybernet Systems acquired Noesis Solutions, the developer of Optimus

- 2013, CD-adapco acquired Red Cedar Technology, the developer of HEEDS

- 2016, Siemens acquired CD-adapco, along with HEEDS; then right after Siemens started to promote optimization-driven design in its global market

- 2019, the CAE giant ANSYS acquired Dynardo, the developer of OptiSLang

All these activities show active momentum of the said trend. In the recent ANSYS acquisition, Navin Budhiraja, vice president and general manager of cloud and platform at ANSYS, said :

“Design space exploration and optimization is key for organizations looking to reduce development time and accelerate the evaluation of optimal product design alternatives for cost and performance.”

Johannes Will, managing director and co-founder of Dynardo, stated,

“With digitization initiatives increasingly taking hold in virtually every major industry ANSYS serves, we see exciting opportunities and look forward to helping establish simulation-based design optimization workflows as the standardized process for customers worldwide.”

Optimization has gone through decades of development . The latest artificial intelligence (AI)-based optimization algorithms have made the optimization tools versatile and practical, completely out of the pure-mathematical realm. These algorithms treat a trial design and its simulation as one data point; they learn from a set of such data points, and they adaptively search for better designs; they do NOT demand mathematical formulation of design problems; they offer design insights and knowledge; and they use little data as compared to learning based on big data.

OASIS, developed and marketed by Empower Operations, is leading AI-based optimization. OASIS applies artificial intelligence, statistics, and mathematical programming technologies to “mine” the simulation or test data, and autonomously and automatically searches for the optimal engineering design solution. Based on simulation, OASIS generates new design, drives the simulation on the new design, learns from the simulation data, and identifies the best design. As shown in the figure below, OASIS automates the design cycle, and finds the best design in a most efficient fashion. In a sense, OASIS is similar to “AlphaGo” from Google since both rely on learning-based optimization algorithms. The difference is that OASIS strives to use the least possible learning samples while the other bases its algorithm on off-line learning from huge number of samples. Moreover, OASIS frees engineers from repetitive trial-and-error and enables them to devote their time on more creative and productive activities.

Figure 3 OASIS drives the design cycle with least cost and time.

While the industry is making simulation easy to use by more people, i.e., “democratization of simulations,” this issue is as equally critical as for optimization. The so-called “one-click” optimization that can be used by non-experts will out date the expert-oriented tools currently available in the market. It is very likely that, as some tools including OASIS have demonstrated, future CAD or CAE tools will include an optimization button that is easy to use and fully embedded in the design environment.

In 2013, when I was the Technical Committee Chair of the International Design Automation Conference (IDAC), I organized a special workshop of world-leading field experts to reflect on what we have achieved in the past 30 years and what to do in the next 30 years. Optimization was one of the hot keywords that bridge the past and the future. I have seen the development of optimization algorithms and tools in the past, I am seeing applications of optimization-driven design in industries, and I firmly believe optimization-driven design will be a standard practice for all design engineers in the next 5-10 years. These include both product design engineers and process design engineers. Optimization-driven design is the third wave of design technology evolution after CAD and CAE. Whoever sees the trend and invests in it will rise to be the leader of tomorrow.